The Importance of Rubber Work Boots at Lowe's A Comprehensive Guide

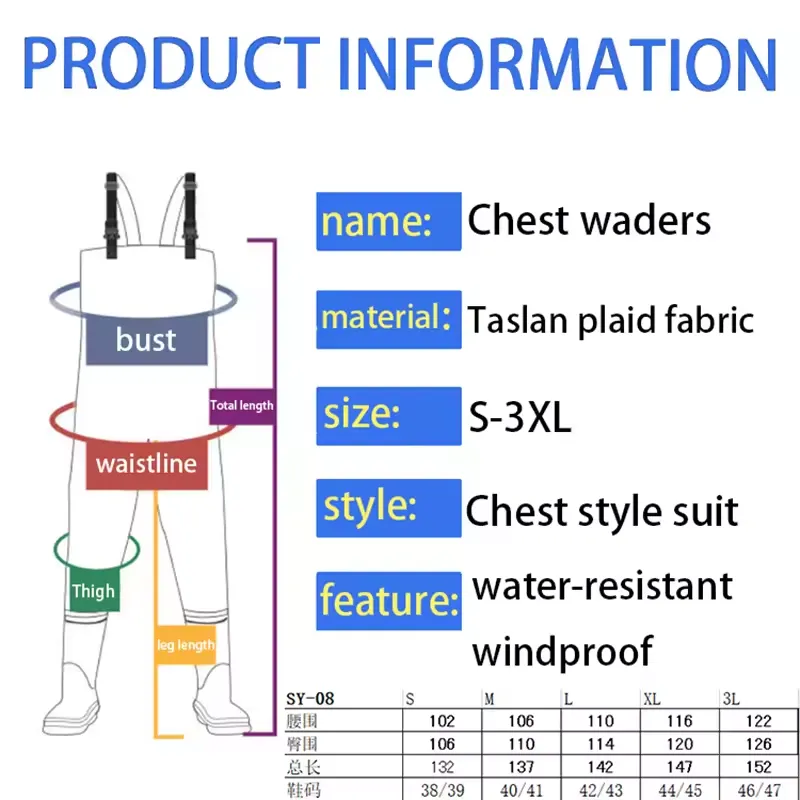

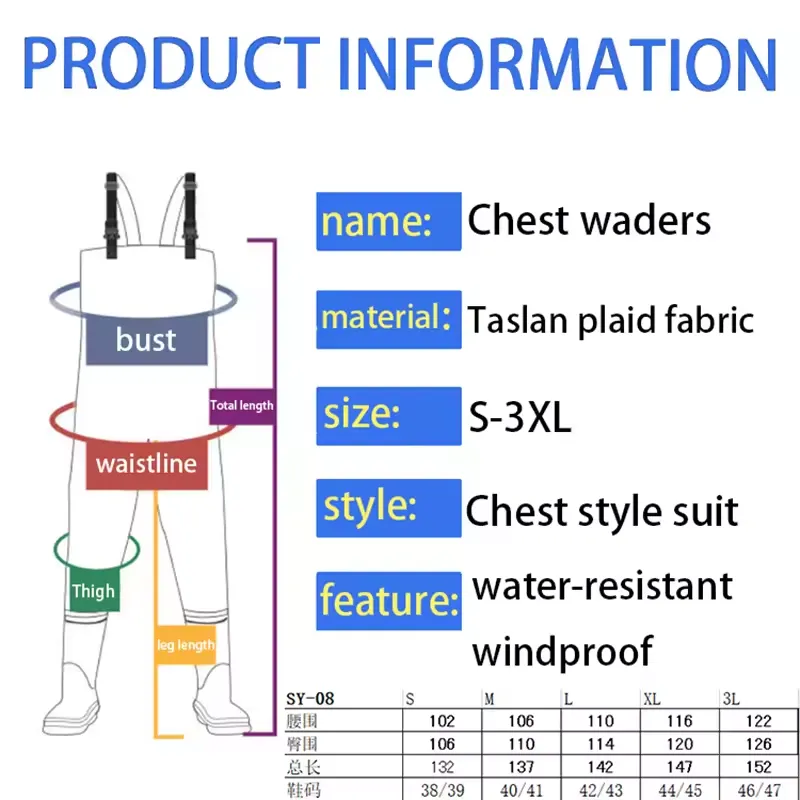

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content

The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content The result is a wader that withstands the rigors of fishing while keeping the wearer dry and content big and tall waders.

big and tall waders.In summary, military camouflage boots, army camo boots, and army camouflage boots are crucial for military personnel and outdoor enthusiasts who require durable, protective, and camouflaged footwear for tactical operations and rugged environments. These specialized boots provide wearers with the necessary support, protection, and camouflage to navigate challenging terrains and perform effectively in military and outdoor settings.

Secondly, let’s look at the importance of waterproof camouflage boots. In humid environments, a pair of waterproof hunting shoes can effectively prevent moisture penetration and keep feet dry. This is essential for extended outdoor activities to avoid foot discomfort caused by wet shoes. At the same time, the camouflage design makes it easier for hunters to blend into the environment in the wild and improves the success rate of hunting.

Composite toe neoprene boots are designed with a protective toe cap made from non-metallic materials, typically consisting of a mix of materials such as Kevlar, plastic, and fiberglass. This innovative design offers safety similar to that of steel-toe boots without the added weight. Neoprene, a synthetic rubber, is used in the boot's construction, providing excellent flexibility, waterproofing, and insulation.

In the realm of hunting, success often hinges on the ability to move through the wilderness undetected. Whether stalking elusive game or navigating dense terrain, hunters rely on stealth to get closer to their prey without alerting them to their presence. One often-overlooked aspect of achieving stealth in hunting is the choice of footwear. Enter neoprene hunting boots – a silent yet formidable ally in the pursuit of stealth and success in the wild.

Moreover, Hunter understands the importance of grip and traction when it comes to walking boots. Many of their styles feature specially designed outsoles that offer excellent traction on uneven surfaces. This is particularly beneficial for hikers and nature enthusiasts who often encounter slippery rocks or loose gravel. With Hunter boots, wearers can confidently tackle a variety of landscapes, from rugged hills to forest trails.

Another benefit of insulated safety wellington boots is their durability

. These boots are made from high-quality materials that are designed to withstand tough working conditions. This means that they will last longer and provide reliable protection for your feet, no matter how challenging the environment.

Hunting season is just around the corner, and as every hunter knows, having the right gear can make all the difference. One essential piece of equipment that every serious hunter should invest in is a pair of high-quality hunting boots. When it comes to hunting boots, one name that stands out is Thinsulate.

Moreover, economic factors such as manufacturing costs, tariffs, and global supply chain issues also influence sports shoe prices. With many sports shoes produced overseas, any fluctuations in labor costs or import duties can have a direct effect on the retail prices. Brands must balance these costs while maintaining their profitability in a competitive market.

Fishing often involves being near or in water, where the potential for wet feet is high. Standard boots may keep your feet dry temporarily, but they often lack the insulation needed to maintain warmth when temperatures drop or when you're standing for long periods. Insulated waterproof fishing boots combine durability, comfort, and water resistance, creating an ideal blend for fishing enthusiasts.

Lightweight soles, equipped with responsive cushioning systems, absorb shock and reduce the impact on joints, allowing for a smoother and more comfortable stride Lightweight soles, equipped with responsive cushioning systems, absorb shock and reduce the impact on joints, allowing for a smoother and more comfortable stride

Lightweight soles, equipped with responsive cushioning systems, absorb shock and reduce the impact on joints, allowing for a smoother and more comfortable stride Lightweight soles, equipped with responsive cushioning systems, absorb shock and reduce the impact on joints, allowing for a smoother and more comfortable stride mens leather athletic shoes. Strategically placed traction patterns on the outsole guarantee grip and stability, while breathable linings and padded collars offer supreme comfort.

mens leather athletic shoes. Strategically placed traction patterns on the outsole guarantee grip and stability, while breathable linings and padded collars offer supreme comfort.In conclusion, ladies' fashion rain boots have moved beyond their original purpose of merely keeping feet dry. They have transformed into a stylish and versatile accessory that can elevate any outfit. The blend of fashion, comfort, and functionality has made rain boots a must-have item in every woman’s wardrobe. With the ongoing innovations in design and materials, it’s clear that rain boots are here to stay, not just as a practical solution for wet weather, but as a definitive fashion statement. So next time the forecast predicts rain, embrace the opportunity to flaunt your stylish rain boots while staying dry and comfortable!

Waterproof and durable, comfortable, put on a pair of modern rain boots, immediately incarnation of the street trend, so that your rainy day can also be fashionable out of the street.

1. Waterproof Protection The primary advantage of neoprene waders is their waterproof nature. Given that hunters often work in wet conditions, having reliable protection against water is crucial. Neoprene creates a seal that prevents water from entering the waders, ensuring the wearer remains dry.

Our High Load Capacity (HLC) molded grating is heavy duty, corrosion-resistant and low-maintenance. It’s engineered to carry heavy traffic liketrucks and forklifts. Our molded HLC FRP Grating is available in 4′ x 6′ panels 1.5″ or 2″ deep in Polyester or Vinyl ester resin systems. HLC grating has many advantages over steel grating for performance and cost effectiveness. With a much higher strength-to-weight ratio, molded HLC fiberglass grating is easy to handle, making for quick installation.

It is most commonly used for commercial floors or walkways, and bridges. But it can also be used for ramps, wash bays, platforms, and jetties.

frp launder. The primer ensures that the repair material will adhere securely, preventing future delamination. Once the primer has dried, layers of fiberglass fabric soaked in resin are applied, building up the thickness and strength of the FRP structure. Each layer must be thoroughly dried and inspected before proceeding to the next one.

frp launder. The primer ensures that the repair material will adhere securely, preventing future delamination. Once the primer has dried, layers of fiberglass fabric soaked in resin are applied, building up the thickness and strength of the FRP structure. Each layer must be thoroughly dried and inspected before proceeding to the next one. By adjusting the air pressure, users can fine-tune the force and speed of the drill, making it suitable for a wide range of applications By adjusting the air pressure, users can fine-tune the force and speed of the drill, making it suitable for a wide range of applications

By adjusting the air pressure, users can fine-tune the force and speed of the drill, making it suitable for a wide range of applications By adjusting the air pressure, users can fine-tune the force and speed of the drill, making it suitable for a wide range of applications air rock drill. From delicately chipping away at a stone carving to aggressively penetrating solid rock for mining or construction purposes, the air rock drill can be customized to fit the task at hand.

air rock drill. From delicately chipping away at a stone carving to aggressively penetrating solid rock for mining or construction purposes, the air rock drill can be customized to fit the task at hand.Zhai Jinguo, deputy general manager and vice president of Shanghai Chemical Institute, said: